Pay • Per • Build

The path to ZERO inventory

You read that correctly, ZERO INVENTORY. Every manufacturer’s dream is a reality with Bamal Fastener.

After the successful implementation of a VMI program, the tactical deployment of a true Pay-Per-Build (PPB) program with Bamal Fastener can effectively reduce your inventory levels to ZERO. You do not pay for a single production component until it has been consumed on the assembly line. This can result in several hundred thousand dollars shifting completely off of your books!

Typically, a full-service VMI program allows the supplier to manage the inventory that moves through your production facility and minimize the amount of inventory on hand. The basic advantages to a VMI program are obvious, but there is still the issue of complete inventory reduction and the remaining wasteful transactions and re-allocation of valuable resources.

Key

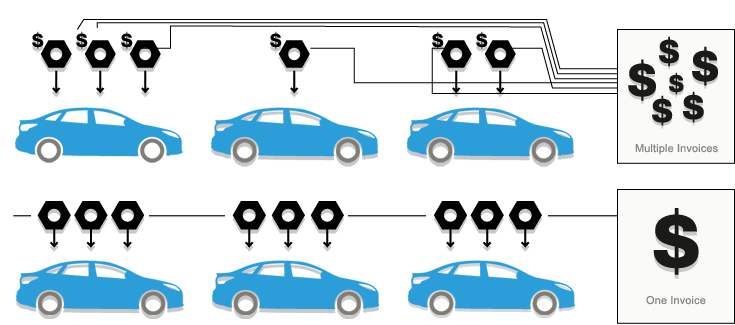

Bamal’s PPB system is simple and it allows us to completely manage your inventory to point of delivery and eliminate all unnecessary transactional costs. Once a stable production cycle has been established for a particular product, Bamal can consolidate the cost of all supplied parts into a single invoice. The basic system is illustrated in the diagram below:

Traditional VMI

Separate bill for each part

Bamal PPB System

Single invoice for all components

Benefits for customers:

- Customer no longer handles multiple invoices

- Customer no longer pays for parts in advance

- Customer no longer requires resources for receiving and handling

- Customer realizes productivity and efficiency improvements

Developed with a focus on volume-oriented production, PPB programs are not limited to customers of a certain size. Every customer is unique and, large or small, we may be able to develop a PPB program tailored specifically to your needs. Contact us today to see how you can take advantage of the Bamal PPB system.